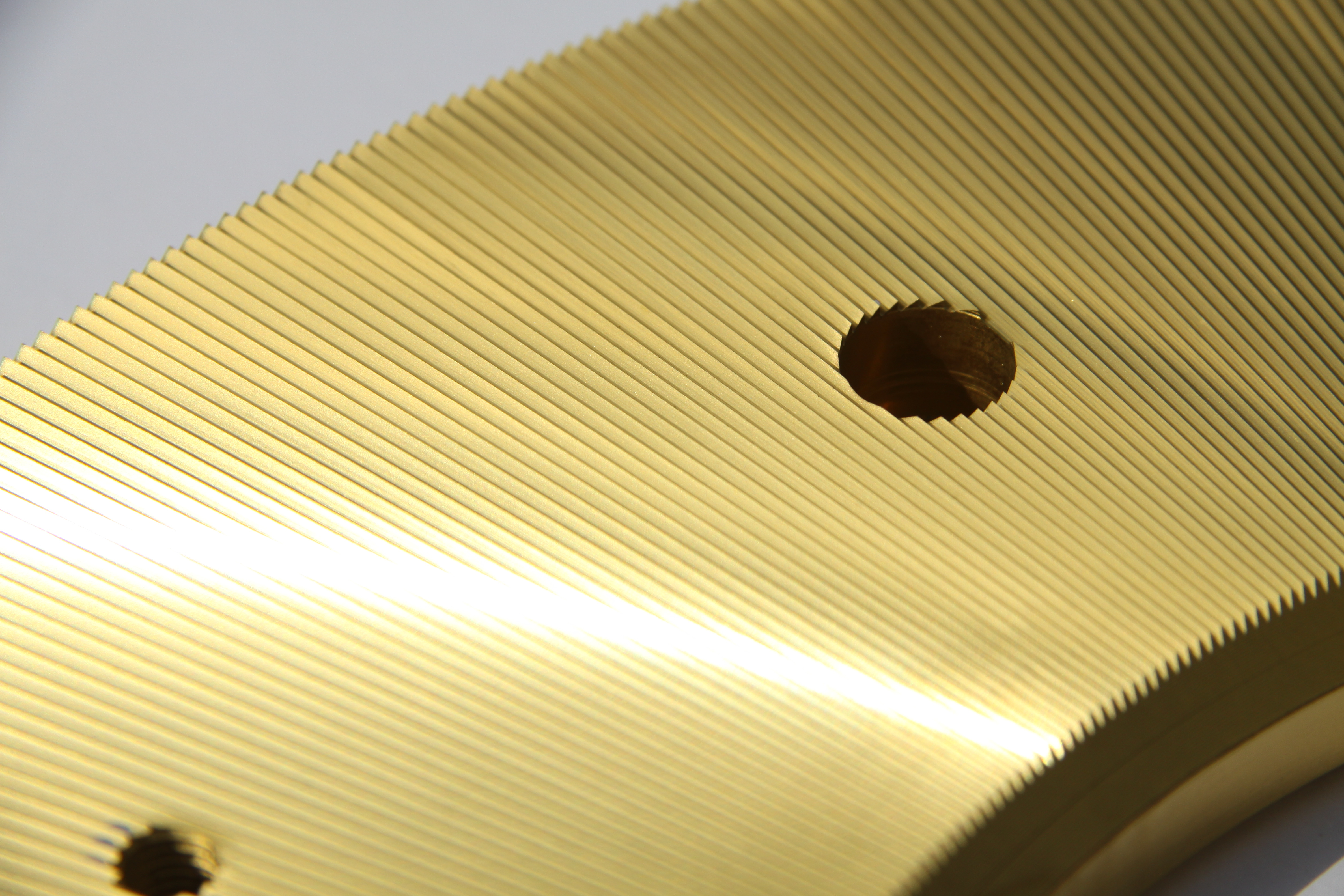

Coating for Industrial Knives and Parts

High performance coatings that extend the lifetime of industrial knives and wear parts. Designed for companies that want consistent quality, predictable lead times and a reliable partner for surface treatment.

Request a Quote

Request a QuoteOur coatings are engineered for industrial environments where uptime and precision matter. Each coating is selected based on wear resistance, friction reduction and thermal stability.

- Non-stick PTFE (Teflon) coatings to minimize adhesive build-up and reduce friction

- TiN (Titanium Nitride) coatings to extend the service life of industrial blades

- Advanced plasma coatings for improved thermal stability and pellet quality

- Corrosion-resistant coatings for chemically demanding environments

- Surface hardness optimization to increase wear resistance

Coating as a Service gives you predictable performance and a clear cost advantage.

- Extended lifetime of knives and wear parts

- Lower friction for cleaner cuts

- Reduced sticking in food and plastic applications

- Lower total cost of ownership

What is the typical turnaround time

Most coating jobs are completed within 3 to 7 working days depending on the coating type and tool size.

Can you coat custom or OEM parts

Yes. We support custom geometries and OEM components.

Do you offer pickup and delivery

Pickup and delivery are available for customers in the EU on request.

Coating Applications

Coatings are suitable for a wide range of industrial knives and wear parts. They help maintain sharpness, reduce sticking and improve overall tool stability.